Caterpillar Lift Trucks San Jose

How to lessen the cost of damage to fork lift trucks

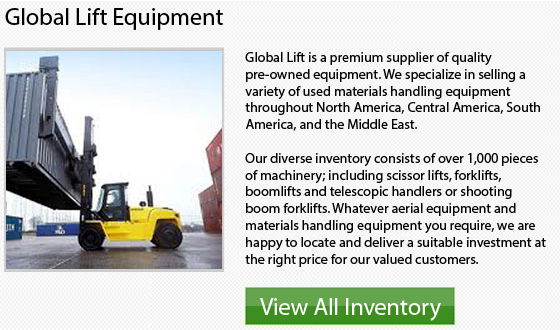

There are several common reasons for forklift truck damage, no matter what the workplace may be. Instances of damage can be very pricey. Costs usually relate to costs of repair and staff downtime. Fortunately, most kinds of forklift truck damage can be avoided. By following these simple steps, fleet operators could make sure that downtime and repair costs are avoided or minimized.

Checking if the machine is appropriate for the surroundings and the task is a good idea. Perform safety checks on truck parts and important systems. Be certain that forklift drivers are well trained and that supervision is provided. Look at the layout of the operating area/warehouse to make certain it facilitates movement. Develop a maintenance/repair plan that could guide actions when anything goes wrong.

Even if the working surroundings is commonly the cause of accidents, fault can be sometimes be the actions of the drivers. A safe working surrounding includes having the right machinery for the application.

The most cost-effective method is to take a coordinated and long-term view of fleet management. The instances of damage could be reduced a lot by having the very same company that supplied the trucks carry our maintenance and repairs and train the drivers. The company can also give recommendation regarding the design of the warehouse.

- Clark Dual Fuel Forklifts San Jose

Clark Forklift Specifications Kinds narrow aisles, pneumatic trucks and cushion trucks are only amongst the various kinds of forklift trucks made by Clark. The various types differ in terms of the way they are powered.... More - Crown Narrow Aisle Forklifts San Jose

Very Narrow-Aisle Turret Trucks In the lift truck industry, Crown has made an innovate line of heavy-duty turret trucks, setting a new level of standard. Crown has designed the fastest travel speeds and the fastest... More - Manitou 4 Wheel Drive Forklift San Jose

Vertical Masted Forklift The vertical masted or straight masted lift truck is a great equipment for your material handling needs. These types of machines are an ideal choice for times where both maneuverability and stability... More - Clark LP Forklifts San Jose

How to Fill Forklift Cylinders Liquid propane is usually used to operate industrial lift trucks or forklifts. There is the choice to have refueling capabilities on site or to have cylinders delivered to your facility.... More - Manitou Telehandlers San Jose

The telehandler is a construction vehicle that is engineered to lift heavy weights and materials. It is really considered to be a hybrid of the crane and the forklift in terms of its capabilities and... More