Jungheinrich Dual Fuel Forklift San Jose

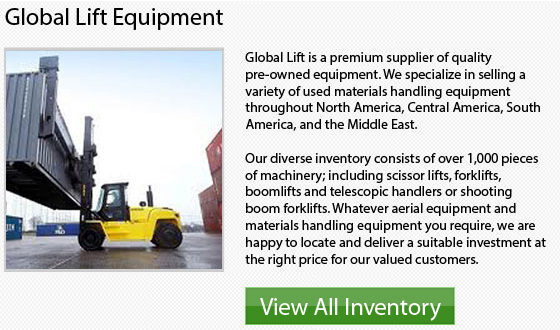

Important equipment utilized on construction sites includes vehicles like the lift truck, the bulldozer and the bobcat. Lift trucks could vary from very big to fairly small units. They are designed to raise loads and move supplies and goods in retail or warehouse settings. Many are designed to maneuver easily in narrow, confined areas. It takes training and skill to properly use a forklift.

Forklifts can be found in most warehouses because they are important pieces of machinery utilized efficient materials handling. They are usually utilized inside warehouses and stockrooms to place and retrieve large or heavy objects that are kept up high. These kinds of machinery are important for productivity in work environments where there is a small area to store a large variety of stock. These trucks are made to transport big pallets around in warehouses.

Anyone utilizing a lift truck must be trained how to drive and operate this piece of machinery. Training can be done in a formal training setting or on the job. usually training is provided at the workplace. Training and accreditation usually means a pay raise for the person acquiring new skills. Lift trucks have standard operating procedures, that makes it easy to get trained on various kinds of lift trucks.

Smaller machinery accommodate a single operator in the cab and can maneuver in small, tight areas. The larger equipment are huge and can lift trucks, automobiles or other heavy pieces of equipment. Lift trucks could lift thousands of pounds easily.

Construction companies typically give pay increases to employees who undergo the training. Employers will usually send a worker to classes to train on a large piece of equipment. Eagerness to train on a bobcat, a bull dozer or a lift truck would pay off.

- Clark Dual Fuel Forklifts San Jose

Clark Forklift Specifications Kinds narrow aisles, pneumatic trucks and cushion trucks are only amongst the various kinds of forklift trucks made by Clark. The various types differ in terms of the way they are powered.... More - Crown Narrow Aisle Forklifts San Jose

Very Narrow-Aisle Turret Trucks In the lift truck industry, Crown has made an innovate line of heavy-duty turret trucks, setting a new level of standard. Crown has designed the fastest travel speeds and the fastest... More - Skyjack Manlifts San Jose

Skyjack Safety Based on Skyjack, the scissor lift is a kind of specialized industrial machine used specially for positioning workers, their tools and their equipment. Anyone who is preparing to operate this particular kind of... More - Clark LP Forklifts San Jose

How to Fill Forklift Cylinders Liquid propane is usually used to operate industrial lift trucks or forklifts. There is the choice to have refueling capabilities on site or to have cylinders delivered to your facility.... More - Manitou Telehandlers San Jose

The telehandler is a construction vehicle that is engineered to lift heavy weights and materials. It is really considered to be a hybrid of the crane and the forklift in terms of its capabilities and... More